Search this site

Articles by Tim Walsh

FAQ: Adhesive Pot Life and Syringe Size

FAQ: Adhesive Pot Life and Syringe Size

What size syringe should you use for your adhesive application? Answer: “It depends.”

Advances in Pre-Mixed and Frozen Adhesives – Appli-Tec Continues to Innovate

Advances in Pre-Mixed and Frozen Adhesives – Appli-Tec Continues to Innovate

With continued innovations, Appli-Tec can “weather” a two-week power outage — ensuring on-time delivery of PMF adhesive materials.

Introducing 1.0 W/mK 5340 Two-Part Thermally Conductive Epoxy in 1:1 Cartridges

Introducing 1.0 W/mK 5340 Two-Part Thermally Conductive Epoxy in 1:1 Cartridges

New 5340 Epoxy – Conveniently packaged in 1:1 dual cartridges for easy mixing.

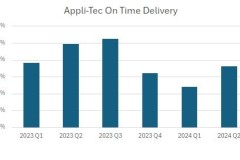

Appli-Tec Achieves Greater than 98% On-Time Delivery

Appli-Tec Achieves Greater than 98% On-Time Delivery

Appli-Tec improved several metrics, including 80% or more of shelf-life remaining for products shipped, shorter lead times, and OTD.

Appli-Tec Introduces 5390 Epoxy with Verified 4.3 W/mK

Appli-Tec Introduces 5390 Epoxy with Verified 4.3 W/mK

Appli-Tec’s 5390 Epoxy is very thermally conductive, electrically insulative, and silver-free.

Appli-Tec Celebrates 40th Year – and a Business Transformation

Appli-Tec Celebrates 40th Year – and a Business Transformation

CEO Tim Walsh’s thoughts on Appli-Tec’s 40th anniversary — and how the company has transformed over the last three years.

The Case for 100% Traceability of Adhesive Materials

The Case for 100% Traceability of Adhesive Materials

Appli-Tec has had 100% traceability for decades. If you’re ever audited, we can tell you who did what, when, where, and how.

Appli-Thane® 7300: First Adhesive Material to Deliver Best-in-Class Thermal Conductivity

Appli-Thane® 7300: First Adhesive Material to Deliver Best-in-Class Thermal Conductivity

Launched in 2012, Appli-Thane® 7300 has become our most requested product.

Appli-Tec Employees Raise $2,118 for NH Food Bank

Appli-Tec Employees Raise $2,118 for NH Food Bank

As part of our People, Planet, Prosperity vision, we held an internal food drive fundraiser.

FAQ: What is the Value of Appli-Tec’s PMF Adhesives?

FAQ: What is the Value of Appli-Tec’s PMF Adhesives?

At Appli-Tec, we test all adhesives to meet our own internal specifications – as well as to customer-supplied specs.

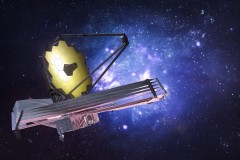

Appli-Tec Part of NASA Goddard Webb Space Telescope Project

Appli-Tec Part of NASA Goddard Webb Space Telescope Project

One of the most complex spacecraft ever made, NASA’s James Webb Space Telescope will allow scientists to break new ground.

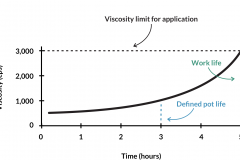

Maintaining Adhesive Viscosity and Work Life

Maintaining Adhesive Viscosity and Work Life

Work life and pot life can vary greatly depending on the adhesive material, its packaging (e.g. frozen, two-part kit), and the application.