Search this site

Articles by Alisha Adams

Do Appli-Tec Adhesives Need a Primer?

Do Appli-Tec Adhesives Need a Primer?

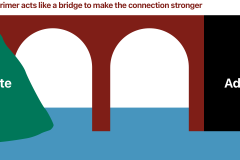

A primer bonds to the substrate and the adhesive — becoming a bridging layer.

Appli-Thane 7800 & 7810 Ideal for Dam and Fill Applications

Appli-Thane 7800 & 7810 Ideal for Dam and Fill Applications

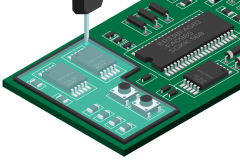

To encapsulate a small section or component of a circuit board, a process called “dam and fill” can be used.

FAQ: “I Have a Difficult Adhesive Mix Ratio. Can Appli-Tec Help?”

FAQ: “I Have a Difficult Adhesive Mix Ratio. Can Appli-Tec Help?”

The impact of mix ratio on adhesive performance is critical and impacts everything from cure rate to outgassing properties.

How Temperature and Humidity Affect Your Adhesive Mix

How Temperature and Humidity Affect Your Adhesive Mix

Temperature and humidity greatly affect viscosity, pot life, adhesive performance, and cured properties.

Room Temperature Cure vs. Oven Cure for Adhesives

Room Temperature Cure vs. Oven Cure for Adhesives

The type of adhesive cure to use depends on your application, what you’re trying to achieve, and your time frame.

FAQ: “Are Appli-Tec Adhesives Solvent-Free?”

FAQ: “Are Appli-Tec Adhesives Solvent-Free?”

95% of our product line is solvent-free – meaning the materials aren’t flammable or have very low VOC emission.

Tech Tip: Bonding Small Electronics to Printed Circuit Boards

Tech Tip: Bonding Small Electronics to Printed Circuit Boards

Learn why bonding components to PCBs is different than metal-to-metal bonding (e.g. aluminum to aluminum).

Three Benefits of Thermally Conductive Adhesives for High Reliability Heat Sink Applications

Three Benefits of Thermally Conductive Adhesives for High Reliability Heat Sink Applications

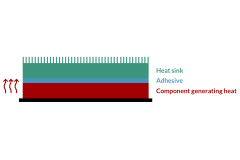

Appli-Tec thermally conductive adhesives eliminate the three challenges associated with thermal grease and pads for heat sink applications.

Bonding – Staking – Potting – Encapsulation:

Bonding – Staking – Potting – Encapsulation: Choosing the Right Adhesive for Your Application

The key difference between potting and encapsulation explained.

Choosing Thermally Conductive Adhesives for Heat Sink Applications

Choosing Thermally Conductive Adhesives for Heat Sink Applications

Solve challenges with heat sink applications that thermal conductive pads can’t handle.

What’s Appli-Tec’s procedure for testing lap shear?

What’s Appli-Tec’s procedure for testing lap shear?

Testing an adhesive’s lap shear is important because it allows for a strength comparison between different adhesive materials on a known substrate.

Shelf Life Considerations FAQ

Shelf Life Considerations FAQ

My Adhesive Material Seems Thicker Than Normal. What’s the Problem?