Search this site

The problems with voids in your cured adhesive include:

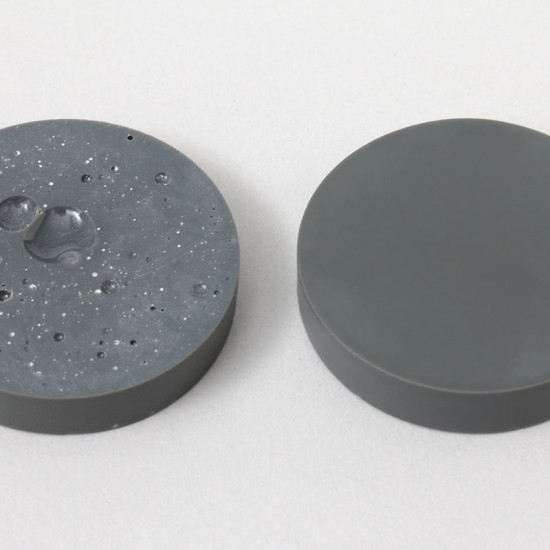

- Pitted surface (Figure 1)

- Reduced bond strength

- Decreased environmental resistance

- Lower thermal and electrical conductivity

Figure 1: Cured adhesive with voids (left) and properly degassed (right)

Why voids occur

Stirring – Mixing multi-part adhesives requires a great deal of stirring, a process that whips in a lot of air, as you can see in Figure 2.

Figure 2: Whipped in air

Viscosity – Thicker adhesives inhibit the ability of bubbles to migrate to the surface.

Fillers – Fillers have micro air bubbles attached to their surface.

Heat Curing – Micro-bubbles expand during a heat cure process. Sometimes many small bubbles combine to make large voids.

Removing bubbles through vacuum degassing

Applying a vacuum reduces pressure, which enlarges bubbles and increases their buoyancy – allowing them to rise to the surface and escape.

Vacuum degassing can be static or dynamic. Mixing under a vacuum (dynamic degas) is the best way to remove trapped bubbles. In Figure 3, you can see the before and after of an adhesive mix that’s been degassed.

Figure 3: Adhesive mix before and after degassing

Vacuum degassing introduces another variable that can affect your mix: contaminants. In next month’s newsletter, we’ll cover the two main reasons why your vacuum chamber could be ground zero for contaminants.

Let Appli-Tec remove your adhesive mixing headache

Engineers rely on Appli-Tec and our packaged PMF adhesives because when a part fails, they know it’s not the adhesive.

Appli-Tec conducts incoming inspection, including FTIR validation, of each adhesive before its use. Our mixing environment is temperature and humidity controlled, and mixing is performed to a documented procedure with every lot number, quantity and time recorded.

It’s why you get consistent results, every single time.

New Applications

I want to discuss my application challenges, order samples, or place a first-time order.

Existing Applications

I need to reorder an existing part number, I have a BOM/Spec.