Search this site

The Use of Specialty Materials in Ultrasound Probes

When engineers hear the word “specialty adhesive,” they usually picture bonding one substrate to another for a critical application, such as one that requires dissipating high heat, or ensuring the cured material doesn’t crack during a thermal cycle.

Depending on the application’s physical properties, resins, hardeners, and fillers can be adjusted to achieve these desired results in both the liquid and cured states.

When we talk about specialty materials, however, we’re talking about something very different. To create a specialty material, we take a liquid thermoset “adhesive” and formulate it in such a way that when it’s cured, it performs a function that may or may not include bonding.

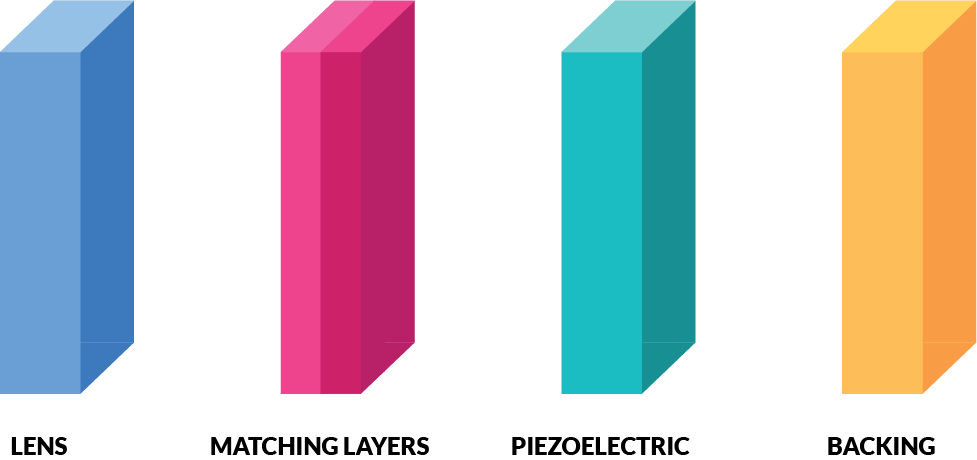

Instead, the material is used in diverse applications to solve specific functions: for example, the medical device industry uses specialty materials to create acoustic lens, acoustic matching layers, and acoustic absorbers or backing materials for ultrasound probes or transducers (Figure 1).

Figure 1: Ultrasound probe

How the specialty material works

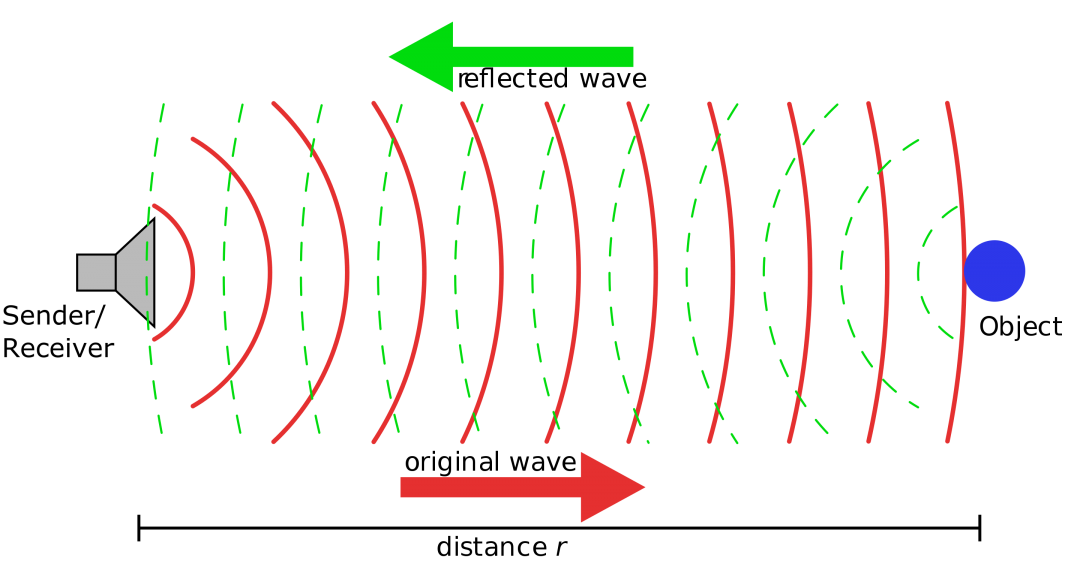

The transducer generates a sound wave (Figure 1), which moves into the body and is reflected back when it encounters something that has a different density. The echo is converted to an electrical signal and finally an image.

Figure 1: Ultrasound wave, courtesy Wikipedia

Within the transducer are found the matching layers and acoustic absorbers (Figure 2).

Figure 2: Layers in an ultrasound probe comprised of specialty materials

Acoustic lens

The acoustic lens material at the head of the probe comes into contact with the patient’s body and thus must be non-toxic, durable, and chemically resistant to the ultrasound gel.

Prior to molding/casting and curing, the “liquid” material from which the acoustic lens is made must be uniformly mixed and air-free. Consistency in color is a major consideration in branding of the final product. Testing of cured samples ensures the impedance of the lens is similar to that of the human body.

Matching layers

Matching layers are usually created from an epoxy, with the inner layer typically containing fillers and the outer layer remaining unfilled. Their purpose is to improve the sensitivity and bandwidth of the sound wave. Impedance matching is used to transfer energy efficiently.

Specialty materials use to create matching layers can be mixed, degassed, cast, cured, tested for velocity, impedance, loss/attenuation and machined to exacting specifications.

Backing, acoustic absorbers

The front end (lens, matching layers, piezo crystal) of the transducer’s purpose is to send and receive the echo of a sound wave. The back end (backing) is used to absorb and scatter sound. Backing and acoustic absorber materials have high attenuation and moderate impedance. Backing materials are processed similarly to matching layers.

Appli-Tec can process your specialty materials

Appli-Tec’s specialty materials are consistently dispersed and can be cured air-free without settling. Due to our precision process, we minimize quality issues — freeing you to focus on improving productivity rather than investigating non-conformity issues.

Do you have a special material that must be precision mixed, degassed, not settle during cure, and be pretested before you use it?

New Applications

I want to discuss my application challenges, order samples, or place a first-time order.

Existing Applications

I need to reorder an existing part number, I have a BOM/Spec.