Search this site

More Info

Calculating a Component’s Total Designed-In Cost

Calculating a Component’s Total Designed-In Cost

How a company’s product and hidden costs can soar due to mixing adhesives in-house.

Controlling Bond Line Thickness

Controlling Bond Line Thickness

To control bond line thickness, get your adhesive premixed and frozen with glass spacer beads added for even disbursement.

How Vacuum Degassing Can Contaminate Your Adhesive Mix

How Vacuum Degassing Can Contaminate Your Adhesive Mix

How vacuum degassing can introduce contaminants into your mix – often unknowingly.

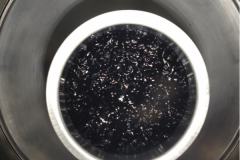

Why You Have Voids in Your Cured Adhesive

Why You Have Voids in Your Cured Adhesive

Mixing multi-part adhesives requires a great deal of stirring, a process that whips in a lot of air.

Adhesive Mix Variables that Lead to Failure

Adhesive Mix Variables that Lead to Failure

Three of the more common variables of the mix process that can lead to potential failure.

Appli-Tec Featured in Adhesives and Sealants

Appli-Tec Featured in Adhesives and Sealants

A manufacturer outsourced its adhesive mixing and as a result, reduced contamination and risk while improving productivity.

Polyurethane Adhesives Absorb Stress for Aerospace Applications

Polyurethane Adhesives Absorb Stress for Aerospace Applications

Learn how urethane adhesives help mitigate the stresses of aerospace applications.

Appli-Tec Featured in MH&L for Meeting GHS Deadline

Appli-Tec Featured in MH&L for Meeting GHS Deadline

How Appli-Tec met OSHA’s Hazard Communication Standard for its adhesive products a month before the June 2015 deadline.

Adhesive SDS Now Available on Appli-Tec’s Website

Adhesive SDS Now Available on Appli-Tec’s Website

Print-ready SDS for Appli-Tec adhesive products now available for download.

Case Study: Appli-Thane 7300 Solves Circuit Board Heat Challenge

Case Study: Appli-Thane 7300 Solves Circuit Board Heat Challenge

An engineer turned to Appli-Tec for an adhesive compound with high thermal conductivity and a 4-hour pot life.

Appli-Tec Meets OSHA’s GHS Labeling Requirements

Appli-Tec Meets OSHA’s GHS Labeling Requirements

Becoming GHS compliant took over a year and included having to create labels that met the standard yet also fit size 3cc and 5cc syringes.