Search this site

Choosing Thermally Conductive Adhesives for Heat Sink Applications

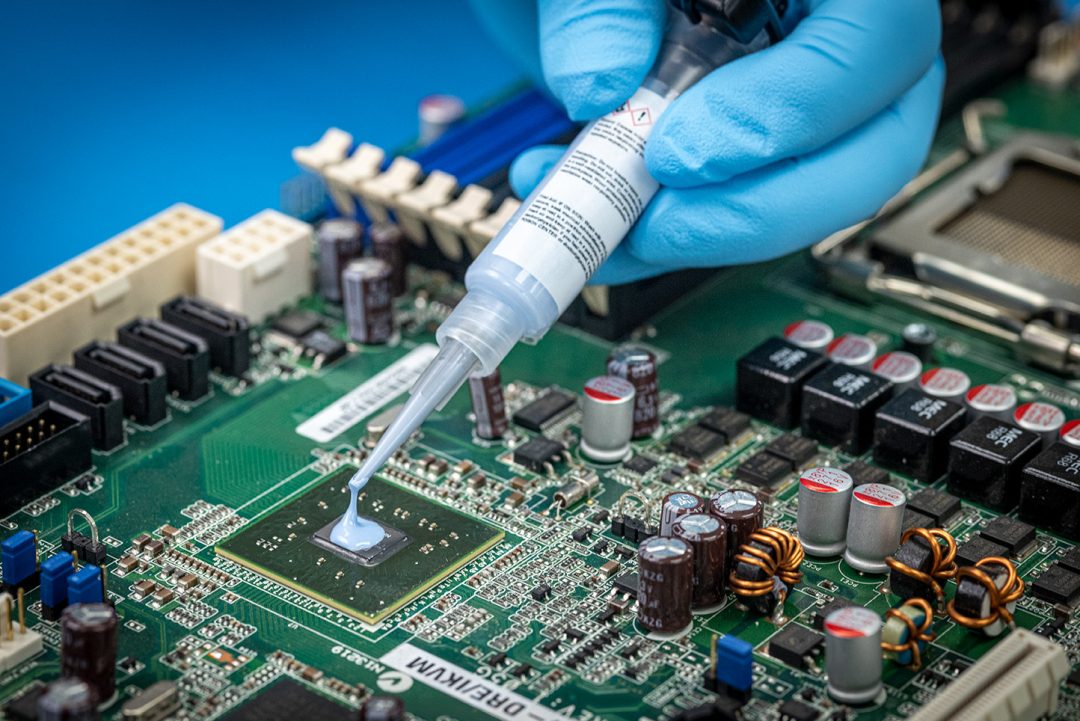

Appli-Thane 7300 adhesive used for bonding application that required maximum thermal conductivity.

When bonding integrated circuits to heat sinks, a thermal interface material, such as a thermal pad or adhesive, is often used to aid in the conduction of heat away from the component being cooled. In this FAQ, we answer some of the questions regarding thermally conductive adhesives.

Q: Why do thermally conductive adhesives provide efficient heat transfer?

Electronics produce a lot of heat, and the smaller they are, the more heat they produce. Just as the name implies, a thermally conductive adhesive aids in conducting this heat away from the components to the heat sink by lowering the thermal impedance between them.

Thermally conductive adhesives serve an additional purpose as well. In order to effectively cool a component, a good physical contact must be formed between the component and the heat sink. Because the surfaces of both substrates aren’t absolutely smooth at the microscopic level, tiny gaps exist – thus reducing the effectiveness of the contact area.

A thermally conductive adhesive fills in these gaps, reducing the thermal impedance, and allows for efficient heat transfer.

Thermally conductive adhesives are used to provide a thermal path between heatsinks and components.

Q: Can I rework a part if I use a thermally conductive adhesive?

For thermally conductive epoxies, you can’t rework a part. This is because epoxies are a harder material. When you remove the epoxy from a substrate, you damage it. This lack of flexibility is why engineers like conductive pads or thermal grease – because it allows them to rework parts.

The downside with thermal grease, however, is that it can bleed out between the substrates, reducing the heat transfer and the bond line thickness. It also doesn’t perform well in high-temperature applications or during thermal cycling.

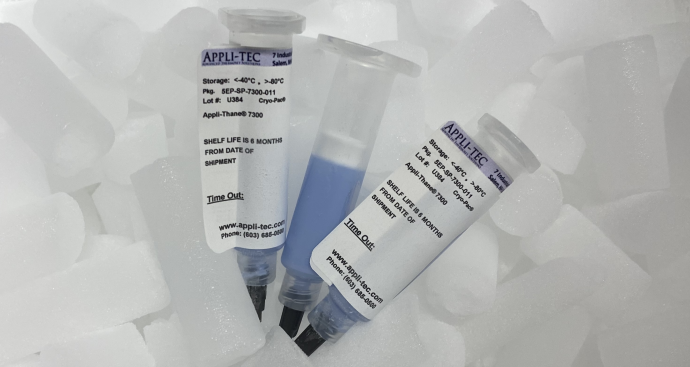

To solve this challenge, we developed Appli-Thane® 7300. A soft, flexible urethane, Appli-Thane 7300 delivers outstanding thermal conductivity and is more flexible than epoxies to accommodate greater high coefficient of expansion (CTE) mismatch between substrates (and thus reduced failure rates).

The material is easily removed for rework or alteration if needed. It also has a long work life and is ideal for automated dispensing.

Appli-Tec’s Appli-Thane 7300 is the company’s most requested adhesive material.

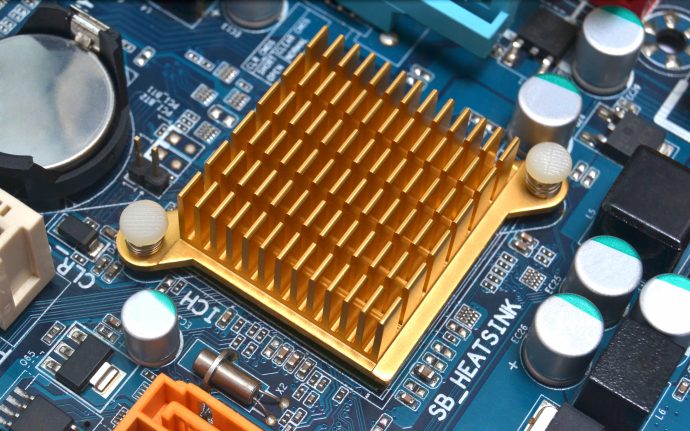

Q: How does a thermally conductive adhesive differ from a thermally conductive pad?

Because an adhesive flows, it follows the topography of the substrate’s surface — eliminating any air gaps and thus allowing for a more intimate and stronger contact between the two substrates being bonded. For these reasons, a thermally conductive adhesive reduces ITR, or interface thermal resistance.

A thermal pad, on the other hand, is flat. It sits on top of the substrate and while it may block air, it doesn’t eliminate air gaps – which can reduce the effectiveness of the bond.

A thermally conductive adhesive has much higher shear strength and reinforces the assembly. It also provides significantly more efficient heat transfer.

Q: What should I consider when choosing a thermally conductive adhesive for my critical bonding application?

It depends on your application and what you’re trying to achieve. Depending on its formulation and material type (e.g. epoxy, urethane or polysulfide), a thermally conductive adhesive can solve a wide range of application challenges. The properties to consider, when choosing your thermally conductive adhesive include:

Thermal properties — The thermal conductivity needed (W/mK) for the application, operating temperature range, and Glass Transition Temperature – to name a few things — are all critically important.

Mechanical factors — Material thickness is important to consider, as well as how and where the assembly is being used (in space, outdoors, subject to extremely low or high temperatures, etc.).

Key features of the material — These include cure temperature, electrical and mechanical properties, flexibility to accommodate joint movement without sacrificing thermal properties, and compliance with chemical specifications.

Pot life — For example, whether you’re using the material with an automated dispenser or applying it manually via a syringe.

Cure time — Do you need the adhesive to cure at room temperature overnight or can you cure in an oven? Remember, longer pot life (over 3 hours) typically means you have to oven cure; short pot life (less than 1 hour) means the adhesive will probably cure at room temperature.

The thermal conductivity needed (W/mK) for a heat sink application is important when choosing a thermally conductive adhesive.

Q: What types of thermally conductive adhesives do you offer – and can you pre-mix them for me?

Please see our Adhesives Materials page for a list of thermally conductive materials and their corresponding TDS. If you need a custom formulation, our engineers can work with you.

Yes, we can mix your adhesives for you, pre-package them for manual or automatic dispensing, and then flash freeze at -40C. Please see our PMF Adhesives page for more information.

If you know exactly what you need, and the quantity, you can complete our brief RFQ form.

New Applications

I want to discuss my application challenges, order samples, or place a first-time order.

Existing Applications

I need to reorder an existing part number, I have a BOM/Spec.