Search this site

Primers have several functions when applied to a substrate before the adhesive, including increasing bond strength and providing corrosion and moisture resistance to the bond line.

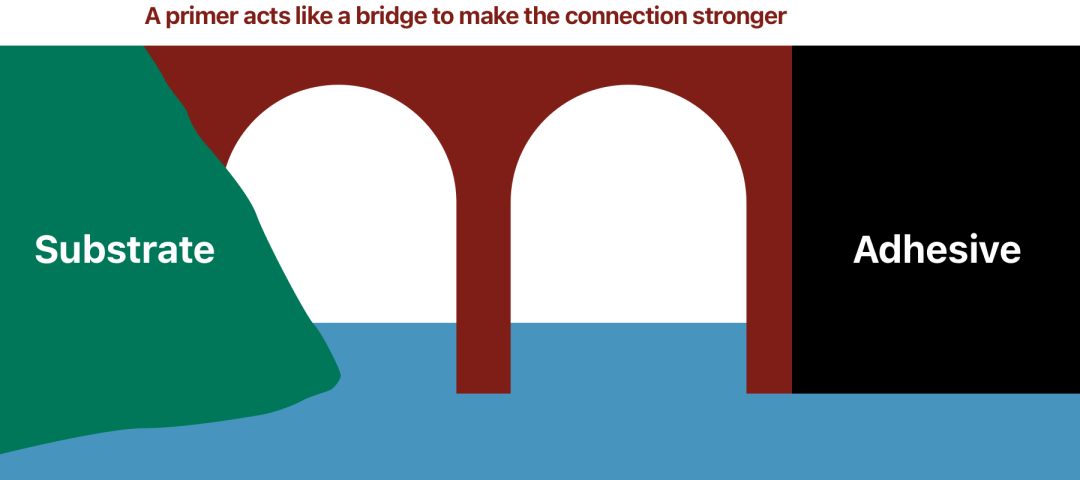

A primer’s main functionality is that it bonds to the substrate and to the adhesive — becoming in effect, a bridging layer. Low surface energy substrates such as polyethylene (PE), polypropylene (PP), polystyrene (PS), and polytetrafluoroethylene (PTFE/Teflon), hinder the adhesion process.

The primer “bridge” can increase the adhesive’s bond strength through bonding with the substrate — providing the adhesive with reactive groups with which to bond.

Some primers can provide corrosion resistance and moisture resistance to the substrate and bond line.

Is a primer needed when working with Appli-Tec’s adhesive materials? The short answer: Maybe.

Most of Appli-Tec’s epoxies have high bond strength to a variety of substrates, especially metals and glass. When bonding plastic, a primer may be useful if the plastic can’t be corona- or plasma-treated prior to adhesive bonding.

Our polyurethanes and silicones have lower bond strength than our epoxies, but their bond strength is normally sufficient for the applications for which they’re recommended.

Adhesion strength can be increased by using the appropriate primer for the substrate and adhesive combination.

If you think you want to try a primer, please reach out for specific recommendations.

New Applications

I want to discuss my application challenges, order samples, or place a first-time order.

Existing Applications

I need to reorder an existing part number, I have a BOM/Spec.