Search this site

Appli-Thane 7800 & 7810 Ideal for Dam and Fill Applications

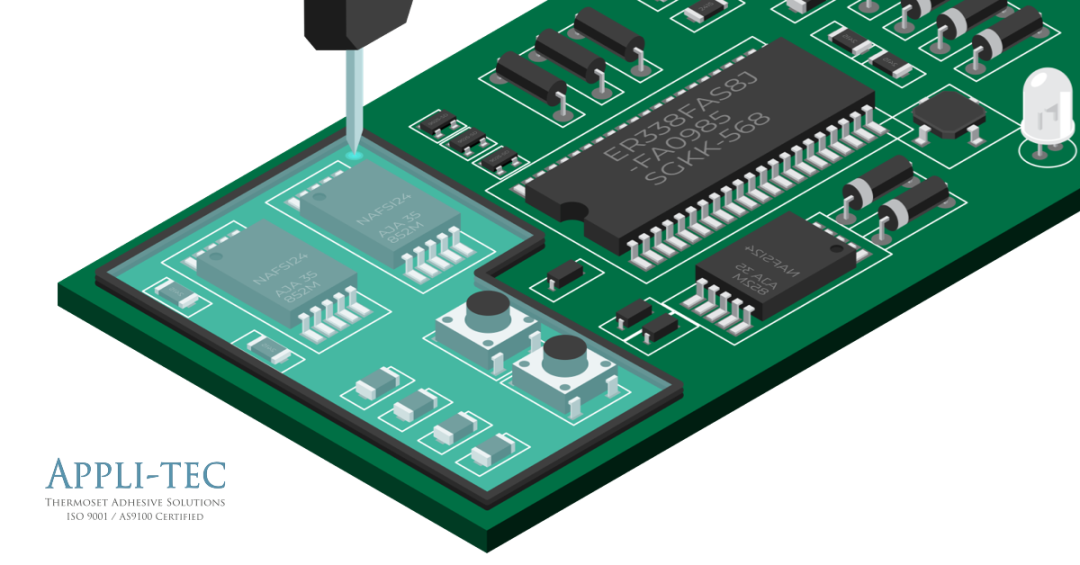

To encapsulate a small section or component of a circuit board, a process called “dam and fill” can be used.

The dam is built in layers using a thixotropic adhesive. A lower viscosity, or flowable, adhesive is used for the fill material. The dam holds the fill material in place during the cure process.

If you’re using dam and fill for a manufacturing run, automated equipment works best for creating the dam as it provides uniform layers quickly and easily.

Two of our adhesive materials, Appli-Thane® 7800 and Appli-Thane® 7810, are well suited for dam and fill applications.

A flexible aerospace urethane, Appli-Thane 7800 features a long pot life and room temperature cure. It also meets NASA’s low outgassing requirements. With low modulus and low Tg, it’s a suitable substitute for many silicones in electronic applications.

A free flowing material, Appli-Thane 7810 is easily reworkable, and meets NASA’s low outgassing requirements.

Have questions about the dam and fill process or using other adhesives? Send your question to one of our technical specialists — see the Contact information below.

New Applications

I want to discuss my application challenges, order samples, or place a first-time order.

Existing Applications

I need to reorder an existing part number, I have a BOM/Spec.