Search this site

Adhesive Tech Tips

Appli-Thane 7800 & 7810 Ideal for Dam and Fill Applications

Appli-Thane 7800 & 7810 Ideal for Dam and Fill Applications

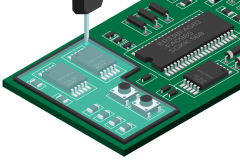

To encapsulate a small section or component of a circuit board, a process called “dam and fill” can be used.

How Temperature and Humidity Affect Your Adhesive Mix

How Temperature and Humidity Affect Your Adhesive Mix

Temperature and humidity greatly affect viscosity, pot life, adhesive performance, and cured properties.

The Case for 100% Traceability of Adhesive Materials

The Case for 100% Traceability of Adhesive Materials

Appli-Tec has had 100% traceability for decades. If you’re ever audited, we can tell you who did what, when, where, and how.

Room Temperature Cure vs. Oven Cure for Adhesives

Room Temperature Cure vs. Oven Cure for Adhesives

The type of adhesive cure to use depends on your application, what you’re trying to achieve, and your time frame.

Tech Tip: Bonding Small Electronics to Printed Circuit Boards

Tech Tip: Bonding Small Electronics to Printed Circuit Boards

Learn why bonding components to PCBs is different than metal-to-metal bonding (e.g. aluminum to aluminum).

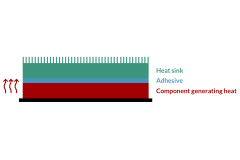

Three Benefits of Thermally Conductive Adhesives for High Reliability Heat Sink Applications

Three Benefits of Thermally Conductive Adhesives for High Reliability Heat Sink Applications

Appli-Tec thermally conductive adhesives eliminate the three challenges associated with thermal grease and pads for heat sink applications.

Bonding – Staking – Potting – Encapsulation:

Bonding – Staking – Potting – Encapsulation: Choosing the Right Adhesive for Your Application

The key difference between potting and encapsulation explained.

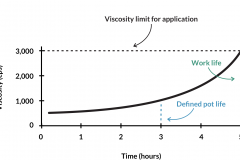

Maintaining Adhesive Viscosity and Work Life

Maintaining Adhesive Viscosity and Work Life

Work life and pot life can vary greatly depending on the adhesive material, its packaging (e.g. frozen, two-part kit), and the application.

Adhesives and Surface Preparation as Part of Your Design

Adhesives and Surface Preparation as Part of Your Design

Surface preparation methods and processes for getting the most from your adhesive application.

Managing the Components in your Adhesive Mixing Room

Managing the Components in your Adhesive Mixing Room

Used in small quantities, minor components can have a disproportionate impact on an adhesive system’s performance.

Calculating a Component’s Total Designed-In Cost

Calculating a Component’s Total Designed-In Cost

How a company’s product and hidden costs can soar due to mixing adhesives in-house.