Search this site

EH&S

Appli-Tec installed 342 solar panels on the building roof in Salem, NH.

Being environmentally conscious in all of our processes is one of Appli-Tec’s strongest values. Whether it’s recycling plastic or adding motion detectors and timers to lights, we’re always looking for ways to reduce, recycle or reuse.

All our EH&S actions tie back to our People, Planet, Prosperity vision and plan.

Environmental

Appli-Tec has installed 342 solar panels, the output of which covers 33% of our electrical consumption each month. Since their installation in August 2018, the panels have generated 612,630 kWh of energy and have offset 260 tons of CO2. We offset about 1 ton of CO2 each week or 52 tons a year.

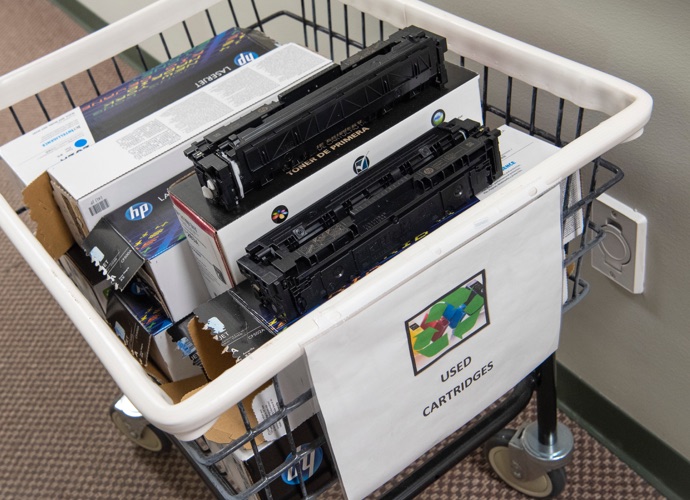

To further our reduction of greenhouse gasses, we’ve installed motion detectors and timers on the LED lights installed throughout our facility. Appli-Tec recycles all metal, plastic, paper and electronic device waste, including toner cartridges. We recycle used machine oil as well.

To further our reduction of greenhouse gasses, we’ve installed motion detectors and timers on the LED lights installed throughout our facility. Appli-Tec recycles all metal, plastic, paper and electronic device waste, including toner cartridges. We recycle used machine oil as well.

The entire team has worked to reduce trash going to landfills by 90%. Efforts include recycling all paper, glass, etc., and having paper towel and food waste picked up by a local company that composts the material. The compost is eventually distributed to local farmers.

In 2015, we added Safety Data Sheets (SDS) to our website to allow customers to download digital files, thus saving on hundreds of paper mailings each year.

Health

Over 95% of our adhesive products incorporate less than 1% solvents in their formulation — meaning they’re solvent-free and have very low VOC emissions. (Read our FAQ.)

Appli-Tec follows all EPA and NH DES regulations regarding hazardous waste. We’re also self-certified with the state of New Hampshire as a small quantity waste generator. This means we list out the types of hazardous waste we produce and then certify we’re storing materials properly by filling out a checklist of actions, and the conditions of our storage facilities and containers, to ensure that we are doing things properly.

The Small Quantity Generator (SQG) Self-Certification Program requires each SQG to review its hazardous waste management procedures, conduct a self-inspection of its facility and certify compliance to NHDES every three years.

Safety

Appli-Tec has been GHS compliant since 2015. All materials that leave our facility follow OSHA’s global labeling requirements for hazardous materials.

All employees are trained in the safe handling of materials and equipment and know how to respond in case of a spill or accident. All proper safety signage and eyewash stations are clearly visible and/or stocked. Appli-Tec has eight employees trained in first aid through the Red Cross – all part of our safety program.

All equipment is maintained and calibrated annually (as applicable). Appli-Tec self-audits the manufacturing facility every month and all safety concerns are addressed in a timely manner.

New Applications

I want to discuss my application challenges, order samples, or place a first-time order.

Existing Applications

I need to reorder an existing part number, I have a BOM/Spec.